- E-mail:info@moldhlh.com

- Tel:+86-198-6410-2854

Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

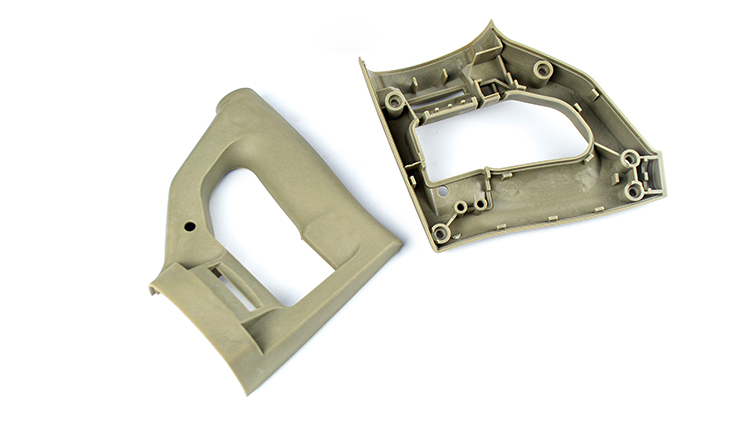

Injection molding is a widely used manufacturing process for producing plastic parts in large volumes with high precision and efficiency. This guide covers the key aspects of injection molding, including its process, materials, design considerations, and advantages, to help you make informed decisions for your manufacturing needs.

Injection molding is a manufacturing process where molten plastic is injected into a mold cavity under high pressure. Once the material cools and solidifies, it takes the shape of the mold and is ejected as a finished part. This method is ideal for mass production due to its ability to create consistent and detailed components.

· Clamping: The mold is closed by a clamping unit to hold it securely in place.

· Injection: Molten plastic is injected into the mold cavity through a nozzle.

· Cooling: The plastic cools and solidifies inside the mold.

· Ejection: The mold opens, and the finished part is ejected.

A wide range of thermoplastics and thermosetting polymers can be used in injection molding. Some of the most common materials include:

· ABS (Acrylonitrile Butadiene Styrene): Durable and impact-resistant, suitable for consumer products.

· Polypropylene (PP): Lightweight and flexible, used in automotive and packaging applications.

· Polycarbonate (PC): Strong and transparent, ideal for optical and electronic components.

· Nylon (PA): High mechanical strength and wear resistance, used in industrial parts.

Selecting the right material depends on the part's mechanical, thermal, and chemical performance requirements.

Effective design is crucial for successful injection molding. Key considerations include:

Maintain uniform wall thickness to avoid warping and ensure proper filling. Recommended wall thickness ranges between 1.2 mm to 3 mm, depending on the material.

Incorporate draft angles (typically 1 to 3 degrees) to facilitate easy part ejection and prevent damage.

Use ribs to reinforce parts without increasing wall thickness and add bosses for assembly points like screws and fasteners.

Strategically place gates (the entry point for molten plastic) to ensure even filling and minimize defects.

Injection molding offers tight tolerances, usually ±0.05 mm, but this depends on material properties and part geometry.

Injection molding offers several benefits for mass production:

· High Efficiency: Fast production cycles enable large-volume manufacturing.

· Precision and Consistency: Delivers accurate and repeatable parts.

· Material Versatility: Compatible with a variety of plastics and composites.

· Cost-Effective: Reduced unit cost for high-volume production.

· Complex Geometry: Supports intricate designs with fine details.

Injection molding is used across numerous industries for producing diverse products, including:

· Automotive: Interior components, housings, and fasteners.

· Medical Devices: Surgical tools, casings, and diagnostic equipment.

· Consumer Goods: Electronics, packaging, and household items.

· Aerospace: Lightweight structural components and fittings.

When selecting an injection molding service provider, consider the following factors:

· Experience: Look for a partner with expertise in your industry and application.

· Material Capabilities: Ensure access to a variety of materials to meet your specifications.

· Quality Control: Verify stringent quality assurance processes and certifications.

· Lead Times: Evaluate production speed and ability to meet deadlines.

· Customization: Assess capabilities for design support and tailored solutions.

Injection molding is a powerful and versatile manufacturing process suitable for producing high-quality plastic parts. By understanding the process, materials, and design principles, you can optimize your products for performance and cost-efficiency. Working with a reliable manufacturing partner further ensures successful project outcomes.

For more information or to get started with your injection molding project, contact us today!

Need more than just injection molding parts? As a full-service manufacturing partner, we offer a complete suite of technologies to bring your entire product to life. From rapid prototyping to mass production, explore our full capabilities in CNC machining, 3D printing, and more at our main site: prototypeshlh.com.