- E-mail:info@moldhlh.com

- Tel:+86-198-6410-2854

Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

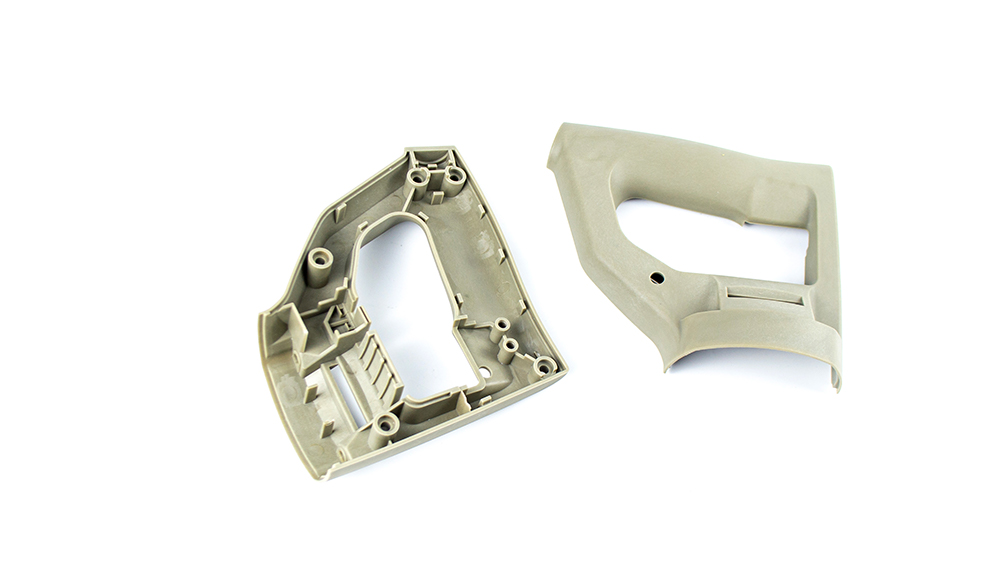

Over the past few decades, China has become a global leader in plastic molding. With strong manufacturing capabilities, advanced technologies, and cost-effective solutions, the country now plays a vital role in supplying molded plastic parts to industries worldwide. From automotive to electronics, China’s plastic molding industry is experiencing rapid growth and continuous innovation.

China’s plastic molding industry has grown alongside rising global demand for lightweight, durable, and cost-efficient products.

· Automotive sector: Plastic components are replacing metal parts, helping reduce vehicle weight and improve fuel efficiency.

· Consumer electronics: Smartphones, home appliances, and wearables increasingly rely on precision-molded parts.

· Medical devices: The need for high-quality, sterile plastic components is driving steady growth in healthcare applications.

Chinese manufacturers have invested heavily in modern plastic molding technologies:

· Injection molding: Offers high-speed, high-precision production for large volumes.

· Blow molding: Used for bottles, containers, and hollow parts.

· Overmolding & insert molding: Combining different materials for added strength and functionality.

· Automation & robotics: Enhancing efficiency, accuracy, and reducing labor costs.

· Cost-effectiveness: Lower production costs while maintaining quality standards.

· Skilled workforce: Experienced engineers and technicians specializing in tool making and production.

· Supply chain strength: Access to raw materials and strong logistics networks.

· Customization: Ability to produce both standard and highly customized solutions for global clients.

While the industry continues to grow, challenges remain:

· Environmental regulations: Pushing companies to adopt sustainable practices and eco-friendly materials.

· Global competition: Other countries are investing in advanced molding technologies.

· Innovation needs: To stay ahead, manufacturers must embrace smart manufacturing and digitalization.

At the same time, these challenges bring opportunities for companies to lead in green plastics, biodegradable materials, and high-performance composites.

The plastic molding industry in China has transformed into a cornerstone of global manufacturing. With advanced technology, competitive costs, and growing expertise, Chinese manufacturers are well-positioned to continue leading the industry. As the demand for precision, sustainability, and innovation rises, China’s plastic molding sector will play an even greater role in shaping the future of global production.

Are you are looking for a plastic molding partner in China? You can contact with HLH, start with a free project review, which you can request here or by https://www.prototypeshlh.com or contact us in this website.