- E-mail:info@moldhlh.com

- Tel:+86-198-6410-2854

Room 2003, 20th Floor, Xingji Building, Shangde Road, Shajing Street, Bao'an District, Shenzhen

Injection molding is a highly efficient manufacturing process used to produce plastic parts with precision and consistency. However, one common challenge designers and engineers face is dealing with undercuts. Understanding what undercuts are, why they can be problematic, and how to design parts to avoid them is crucial for creating functional, cost-effective, and high-quality molded components. In this article, we’ll explore everything you need to know about undercuts in injection molding and provide practical tips for designing parts that avoid these issues.

An undercut is a feature in a molded part that prevents it from being ejected directly from the mold. These features create recesses or protrusions that interfere with the mold’s opening or closing, making it difficult or impossible to remove the part without damaging the mold or the part itself.

· Internal threads or grooves

· Side holes or slots

· Snap-fit features

· Ribs or hooks that extend beyond the part’s main body

Undercuts are often necessary for functional or aesthetic reasons, but they can complicate the molding process and increase costs if not properly addressed.

Undercuts can lead to several challenges in injection molding, including:

-Complex Mold Design: Undercuts require additional mold components, such as sliders, lifters, or collapsible cores, which increase mold complexity and cost.

-Higher Production Costs: More complex molds take longer to design, manufacture, and maintain, driving up production expenses.

-Part Damage: Improperly designed undercuts can cause parts to stick in the mold, leading to deformation or breakage during ejection.

-Longer Cycle Times: Additional mold mechanisms can slow down the molding process, reducing overall efficiency.

While undercuts can’t always be avoided, careful design can minimize their impact. Here are some strategies to help you design parts that reduce or eliminate undercuts:

· Avoid unnecessary features like side holes, threads, or snap-fits unless absolutely required.

· Use straight pull designs where possible, allowing the part to be ejected directly from the mold.

· Incorporate draft angles (typically 1-2 degrees) into your design to make it easier to eject the part from the mold.

· Draft angles are especially important for deep or complex features.

· Replace internal threads with post-molding threading or inserts.

· Use alternative fastening methods, such as adhesives or ultrasonic welding, instead of snap-fits.

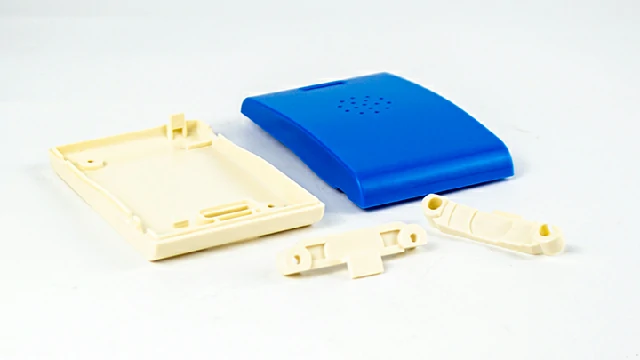

· If undercuts are unavoidable, consider splitting the part into multiple components that can be assembled after molding.

· This approach simplifies mold design and reduces production costs.

· For essential undercuts, incorporate side actions (sliders) or lifters into the mold design.

· These mechanisms allow the mold to release the part without damage, but they add complexity and cost.

If your part requires undercuts, follow these best practices to ensure a smooth molding process:

· Consult with Your Molder Early: Work closely with your injection molding partner during the design phase to identify potential undercut issues and optimize the design.

· Minimize Undercut Depth: Keep undercuts as shallow as possible to reduce the need for complex mold mechanisms.

· Choose the Right Material: Some materials, like flexible plastics, can tolerate slight undercuts better than rigid ones.

· Test with Prototypes: Use rapid prototyping to test your design and identify any ejection issues before moving to production.

While undercuts can complicate the molding process, they are sometimes necessary for functional or aesthetic reasons. Common applications include:

· Snap-Fit Assemblies: Undercuts are often used to create snap-fit connections in consumer products.

· Threaded Parts: Internal or external threads may require undercuts for proper functionality.

· Ergonomic Features: Handles, grips, or other ergonomic designs may include undercuts for comfort and usability.

If your design requires undercuts, ensure they are carefully planned and optimized to minimize production challenges.

Undercuts are a common challenge in injection molding, but with careful design and planning, they can be managed effectively. By simplifying part geometry, using draft angles, and collaborating with your molding partner, you can avoid unnecessary undercuts and reduce production costs. For designs that require undercuts, advanced mold mechanisms like sliders or lifters can help achieve the desired functionality without compromising quality.

At HLH, we specialize in helping our clients design and manufacture high-quality injection molded parts. Whether you’re dealing with undercuts or other design challenges, our team of experts is here to provide guidance and support. Contact us today to learn more about our injection molding services and how we can bring your designs to life!

We are your one-stop shop for all your manufacturing needs. In addition to specialized LSR molding, our main hub at prototypeshlh.com provides access to a full spectrum of manufacturing processes and surface treatments. Join countless designers and engineers who trust us to handle their complete project—from a single prototype to final production.